24 cents & 3/4 pound of wool per yard

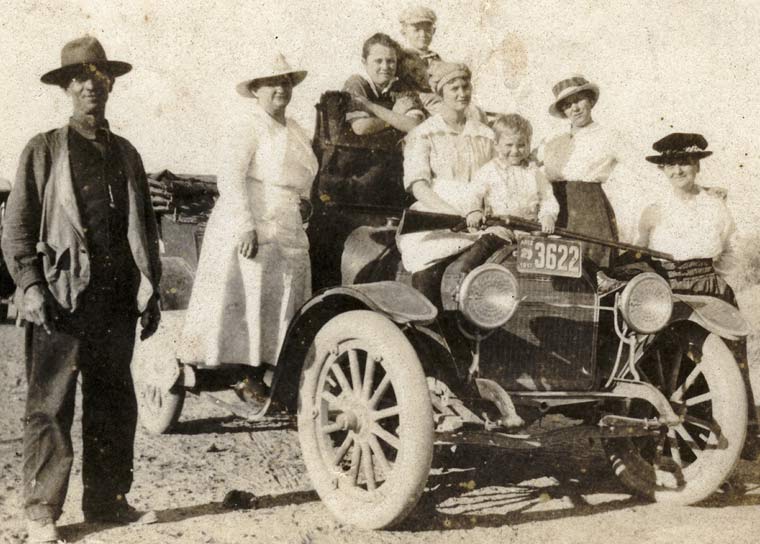

Labels: Poindexter History, WMRd people

For more than one hundred years this was the Place. A community unified by kinship, workplace, church, and agrarian traditions.

Labels: Poindexter History, WMRd people

Labels: Poindexter History

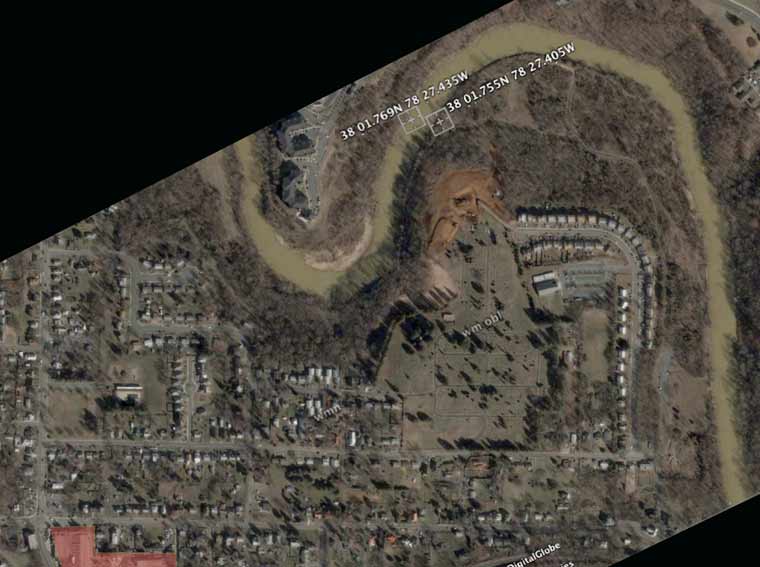

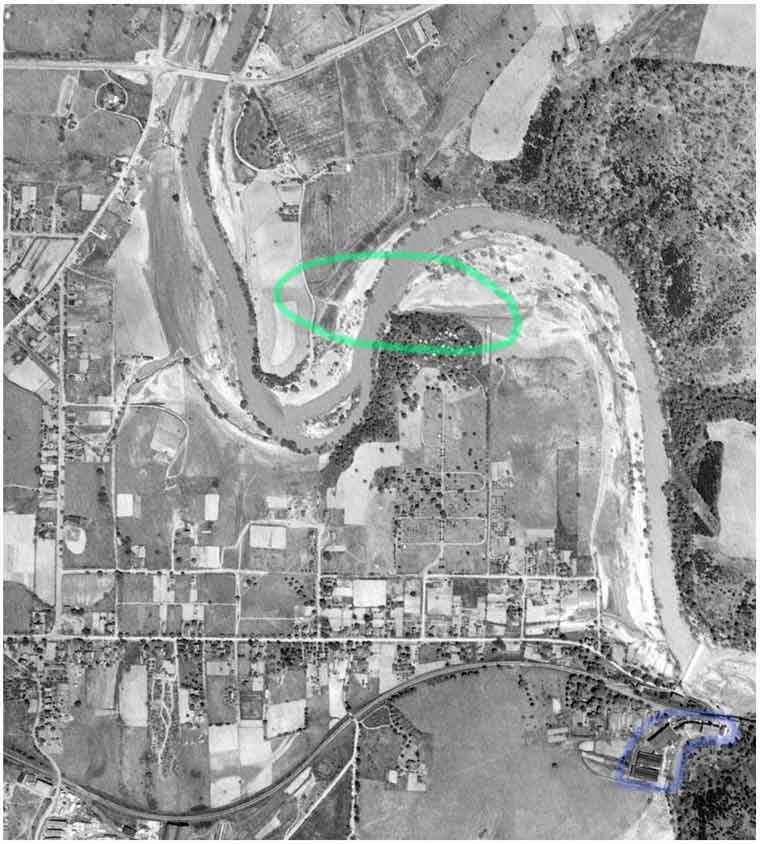

Labels: Moore's Creek, Poindexter History

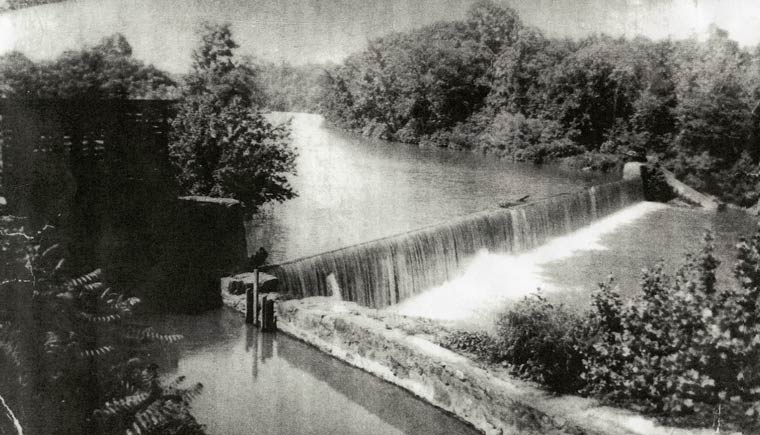

Labels: dam, Poindexter History, Rivanna River

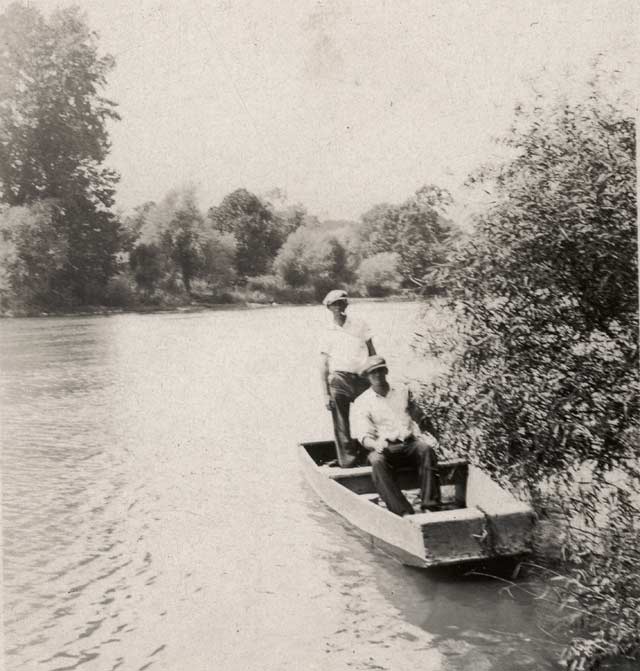

Labels: Poindexter History, Rivanna River

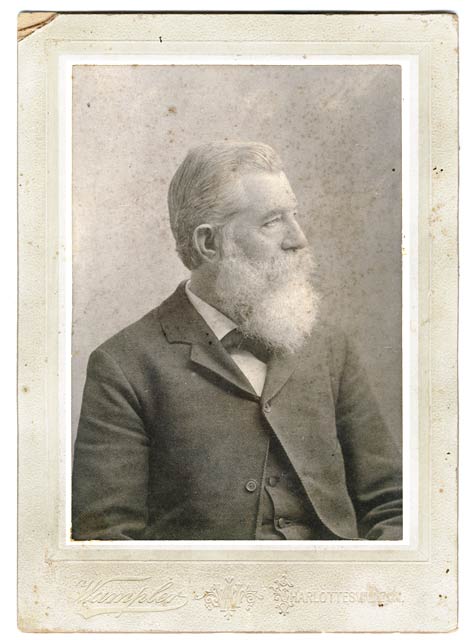

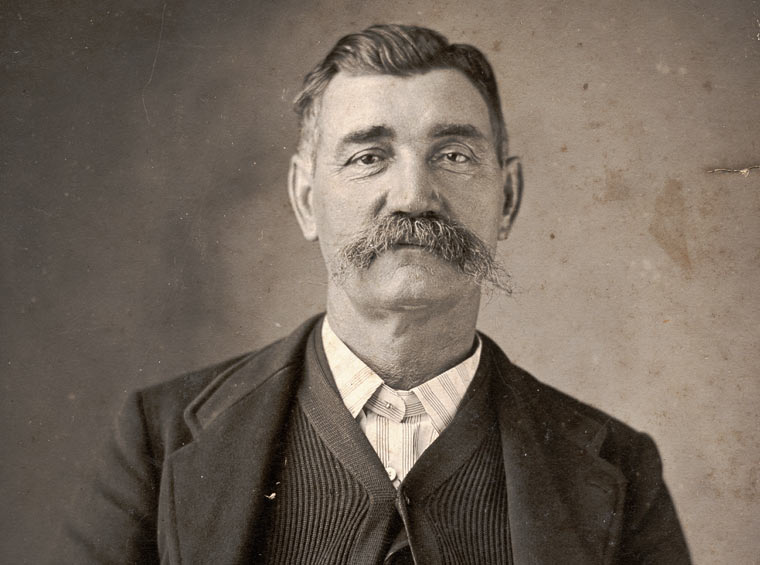

Labels: Henry Clay Marchant, Poindexter History

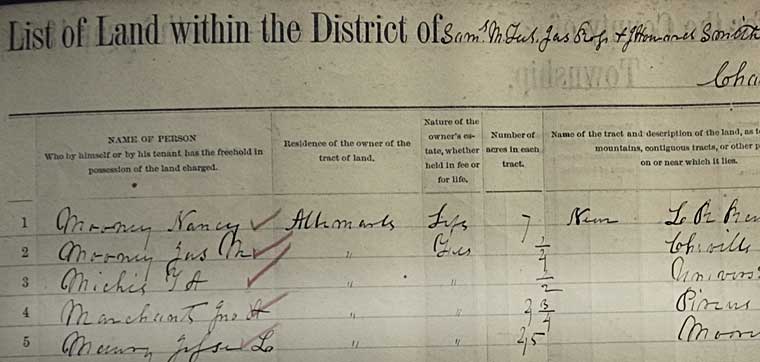

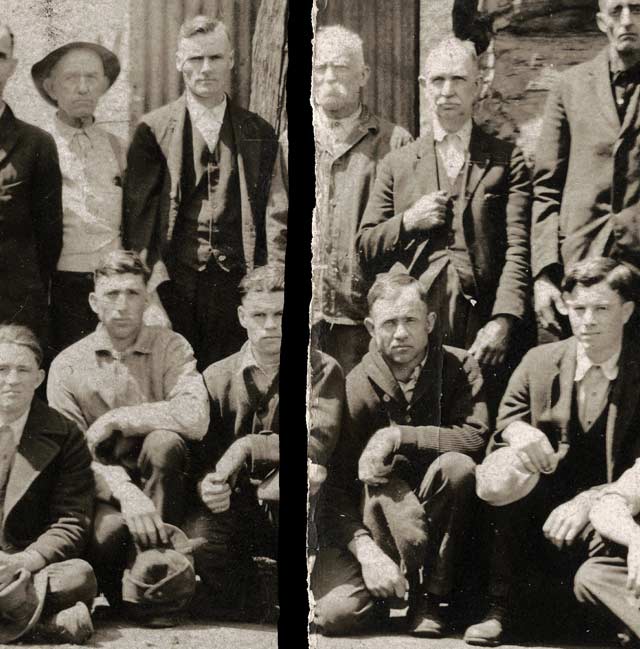

Labels: Poindexter History

Labels: Poindexter History

Labels: Rivanna River

Labels: Poindexter History, WMRd people

Labels: Baltimore, Poindexter History

Labels: Baltimore, Poindexter History

Labels: architecture, Holloway, Poindexter History, Pritchett

Labels: Poindexter History, WMRd people

Labels: Starkes, WMRd people

Labels: architecture, Poindexter History, WMRd people

Labels: Poindexter History, WMRd people

Labels: Poindexter History

Labels: Poindexter History

Labels: Poindexter History

Labels: Poindexter History

Labels: Poindexter History