Damocles

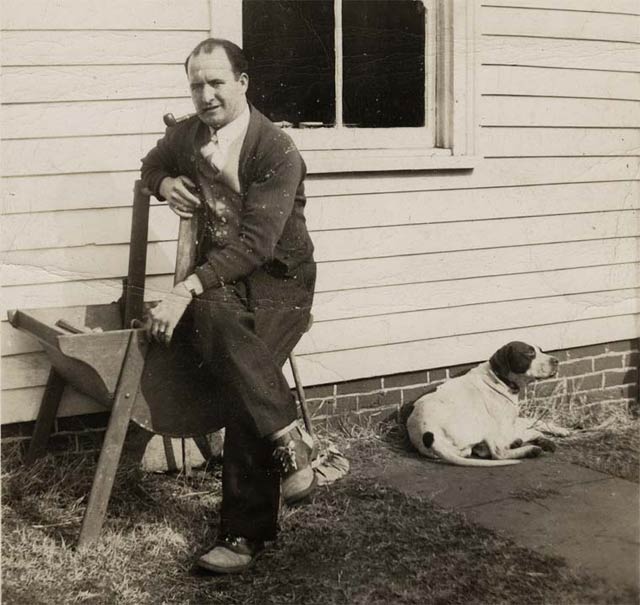

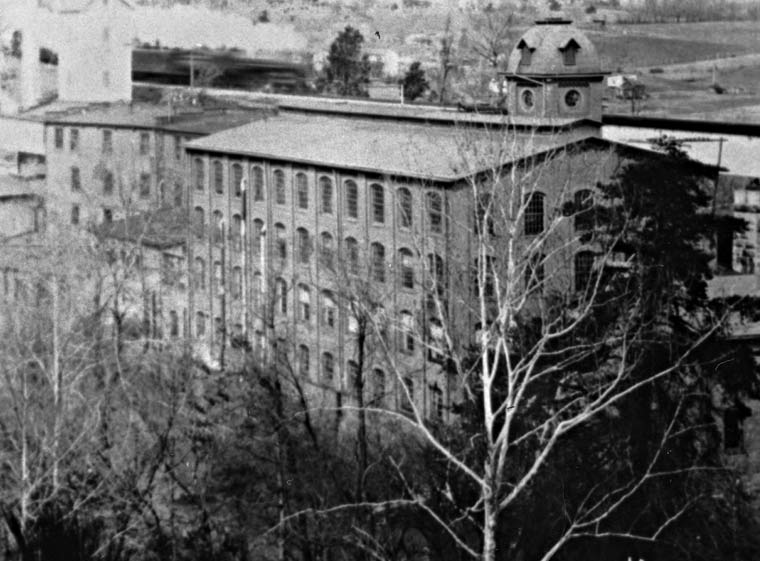

C.E. Mallory purchased two one-acre lots on the north side of Woolen Mills Road (East Market Street) in 1890 (ACDB 94 233). Tax records show that this house was built the next year. It faces east, toward the river and the Woolen Mills. Mallory lived on the other side of Woolen Mills Road, and this house was occupied by his father W.F. Mallory, who made coffins. After his father's death, Mallory sold the property to the Charlottesville Woolen Mills, Inc., in 1897 (ACDB 109-327). The house was enlarged and for fifty years was rented to Howard Tilman, a foreman at the Woolen Hills.-- City of Charlottesville

As the year progressed, the board frequently felt the pulse-beat of the ailing factory and found no sign of improvement. It was clear that some sort of nutrition had to be injected quickly, but what form should it take? Capital stock had already been expanded to $102,000, a mortgage of $48,500 hung like the sword of Damocles over the worried directors, and the company was straining under the burden of loans totaling $50,000. It was estimated that another $50,000 would permit operating at half capacity while $100,000 would place the plant in a condition to compete with other mills and at the same time take advantage of potential markets. In view of "the depressed state of the woolen business which, along with circumstances peculiar to this company, has diminished the market value of its stock," the board saw only one feasible solution: a new stock issue offering inducements and guarantees. --Harry Poindexter

Labels: architecture, Poindexter History