Blair-Seay House

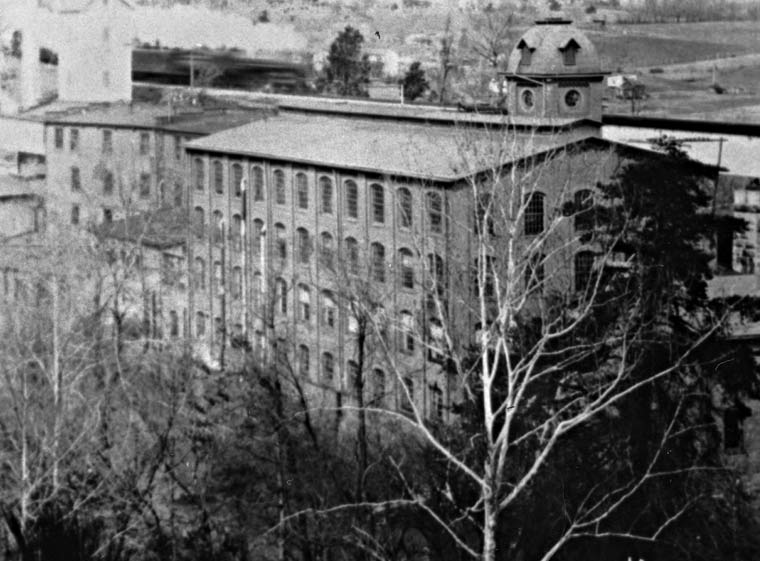

Houses with square or irregular footprints, side-passage plans, front porches, and hipped or complex gabled roofs are the dominant dwelling type of single dwellings built in the 1885-1920 period. Roughly half of the houses built in these years are variations on this type. Some have irregular footprints created by recessed entrance bays. The house at 1709 East Market Street (DHR# 002-1260-0066), for example, is a two-bay, two-story, hipped-roof dwelling with a side-passage plan and an irregular footprint. A flat-roofed, full-width, one-story porch with brackets and lambs tongue chamfered posts shades a single 2/2 double-hung window in the west bay and the door in the recessed east bay. The two second-story bays each have a single 2/2 window. Built in 1889-96 by Archibald Blair, the building has been recently restored and brackets have been returned to the cornice underneath the overhanging eaves. The house at 1606 East Market Street (DHR# 002-1260-0045), built by Mill employees MC and Bettie Harlow in 1916-17, is an outstanding hipped-roof, brick example of this type with a recessed entrance bay. The brick is laid in Flemish bond with glazed headers on all elevations and features a gabled wing on the west that reads as an additional bay from the north-facing fašade.

Some of the early owners of the large lots subdivided the plots and sold parcels to family members. It was common in southern mill towns for people to move to join family members already working in the factories.lxix After purchasing lots 8 and 9 of the Farish land from Henry Bragg in 1889, Archibald Blair built 1709 East Market Street (DHR# 002- 1260-0066).lxx In 1896, he sold the westernmost portion of the lot to his brother, Edward, for $200 and Edward built 1707 East Market Street (DHR# 002-1260-0064) next door soon thereafter. With side-hall plans and hipped roofs, these frame houses are very similar.--Lydia Brandt

Labels: architecture