Senate Bill 957

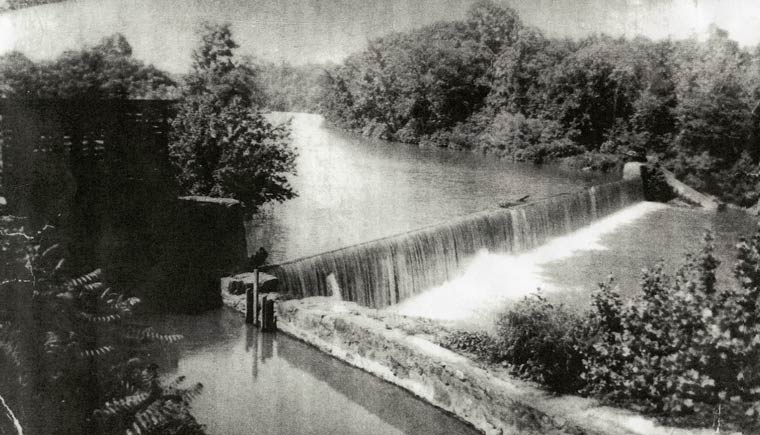

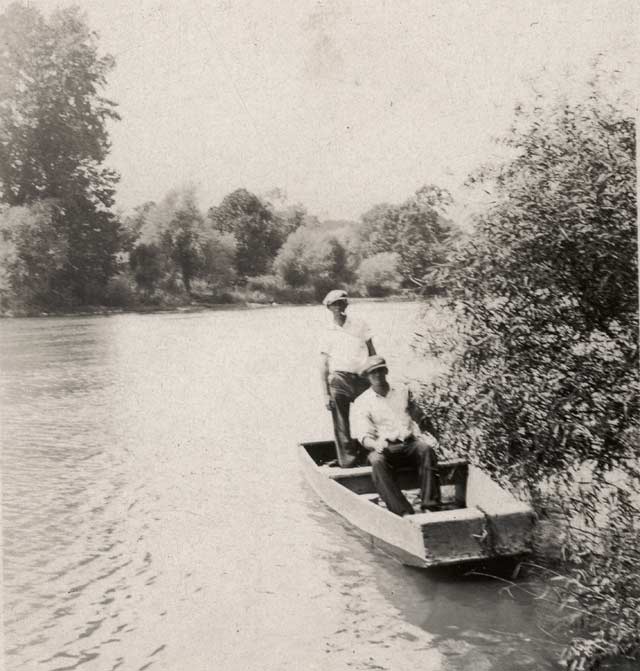

This site is full of references to the Rivanna. The Rivanna River was the center of life for the Woolen Mills Village. For the millenium previous the river had been the center of life for the People of Virginia.

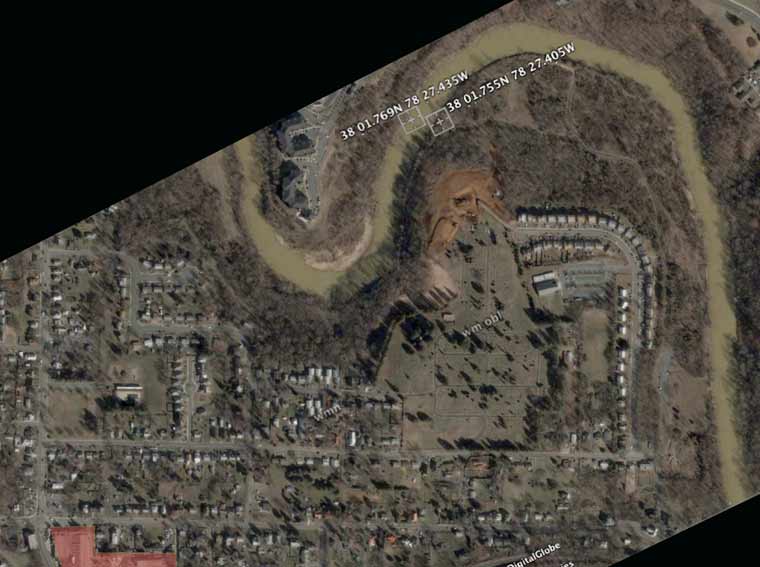

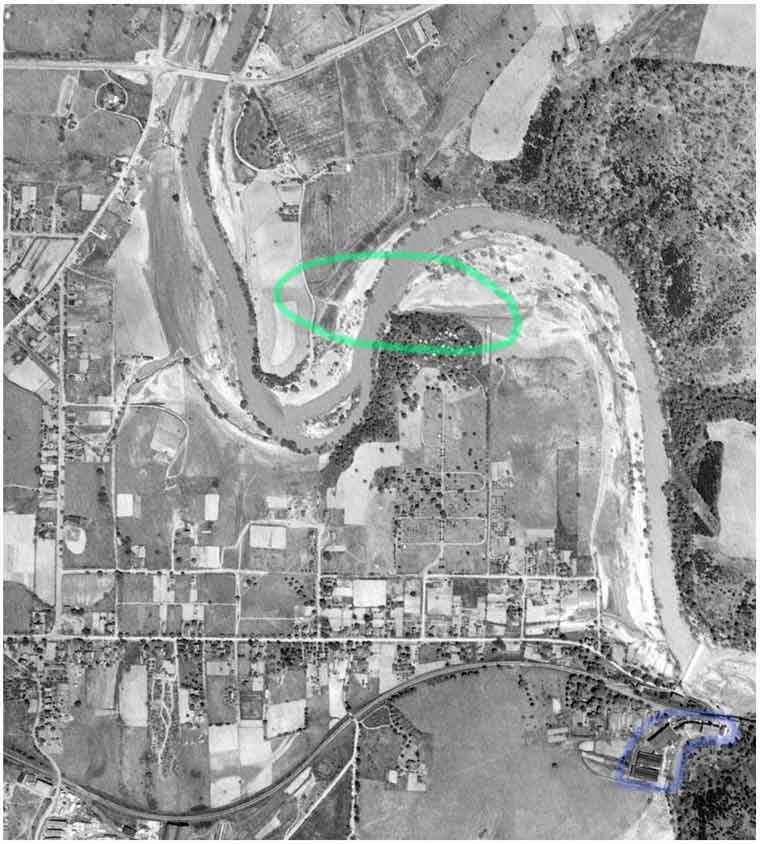

For thousands of years the Monacans were widely dispersed over all of Piedmont and Mountain areas of Virginia. Towards the Late Woodland era, ca. AD 900 - 1700, a pretty strong emphasis of villages on the major rivers for access to transportation and trade and good agricultural soils. From the South Fork Dam east along the Rivanna there is abundant evidence of Monacan villages, as any local farmer or housing developer can tell you, all the way to juncture with the James. --J.L.Hantman

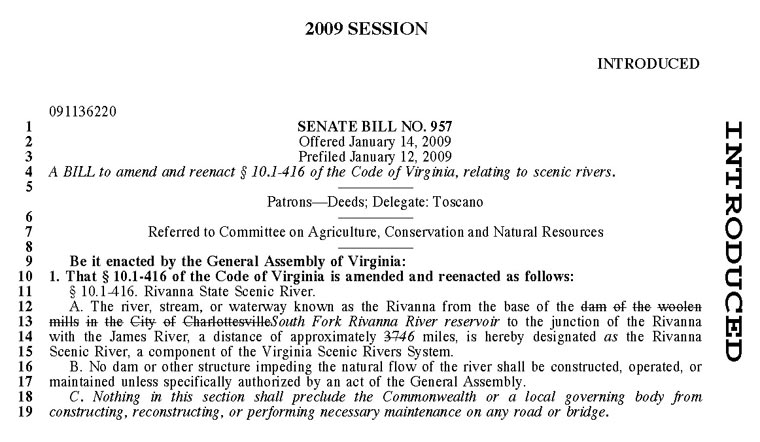

The Virginia legislature is considering the bill above (Senate Bill number 957) which would extend the "scenic river designation" to the Rivanna from the site of the Woolen Mills dam upstream.

Since it annexation of the the right bank of the River in 1963 the City of Charlottesville has taken slight advantage of this asset. Possibly, with state recognition, the City will take another look at this jewel at its feet.

Labels: Rivanna River